Method for treating and obtaining sub-products from residues proceeding from olive mills

The present invention tries to solve the problem of the sub-products or solid and liquid wastes from olive mills. Olive pomace, “alpeorujo”, olive pit, “alpechín”, water used for washing olives , water used for washing oil and brine are considered as residues from olive mills.

The residues obtained in the treatments used in olives in olive mills for obtaining olive oil do not accomplish the regulations to be spilled in public courses or sewage systems, nor used for irrigation activities due to the highly contaminant charge. Those wastewaters show a high amount of residues, such as dust, soil, oils and fats, carbohydrates, nitrogenated substances, organic acids, polyalcohols, polyphenols, etc. Among them, polyphenols and fats are the ones that show bigger problems, due to their polar and hidrophobic properties, respectively. The way for eliminating those polyphenols is through a physical-chemical process, due to the inhibition activity that show over microbiological processes.

The traditional way for treating waste products has been the storage in ponds, where the residue is being reconcentrated through time, so the contaminant power progressively increases. Another problem is that the capability of the ponds is limited, leading to build new ponds, which entails associated problems such as possible overflows, penalties and paralyzation of activities, slowing down the implementation of quality management systems, air pollution and plagues of several insects species.

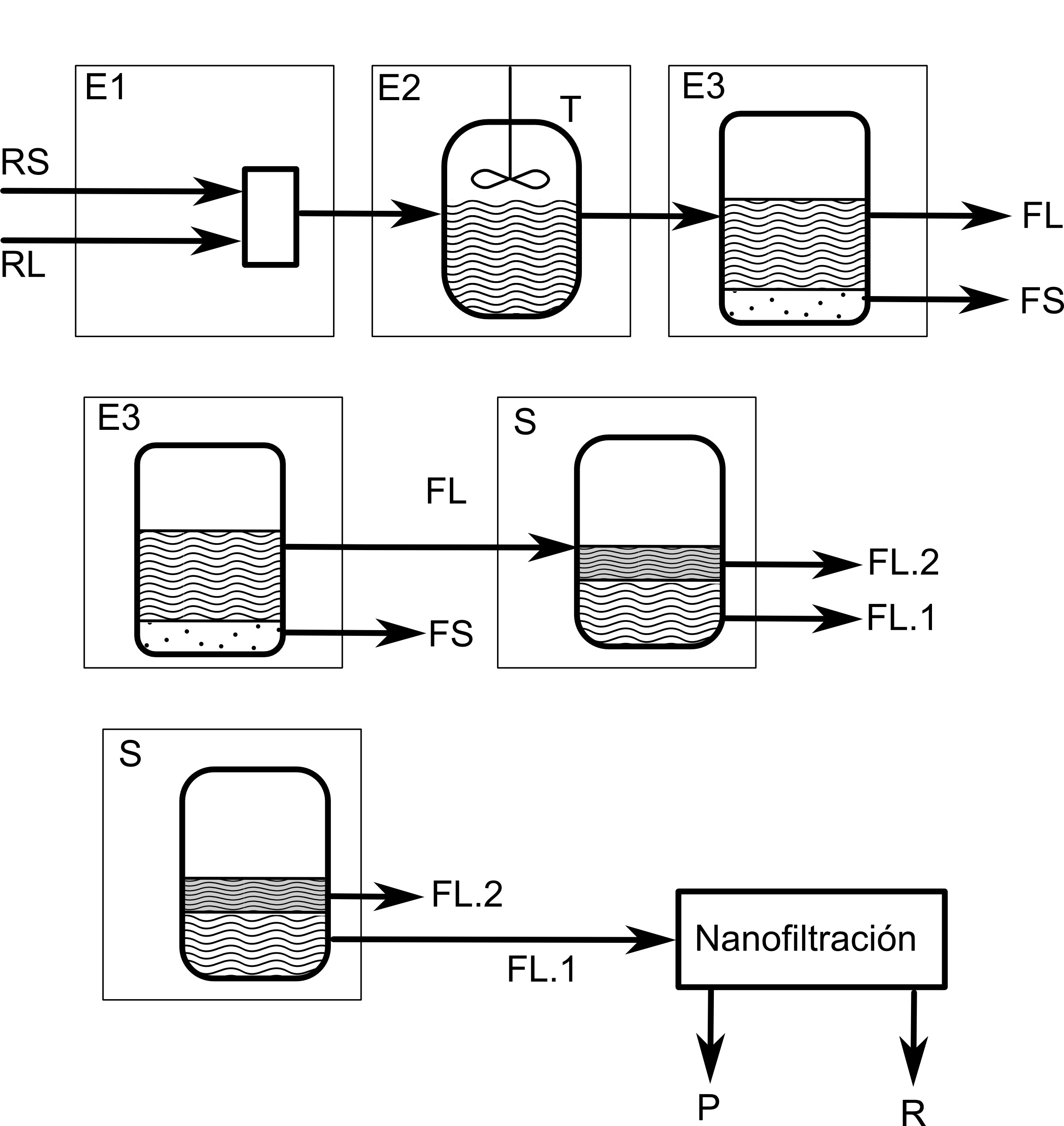

The present invention depicts a new procedure for treating these residues, consisting in:

-

Mixing solid and liquid residues.

-

Solid-liquid extraction of the compounds of interest.

-

Solid-liquid separation. In that process stage, a solid and a liquid phases are obtained, where the aqueous phase is enriched with all the compounds of interest and the oil-phase contains residual olive oil.

-

Finally, through nanofiltration, the compounds present in the liquid phase are obtained (polyphenols and antioxidants).

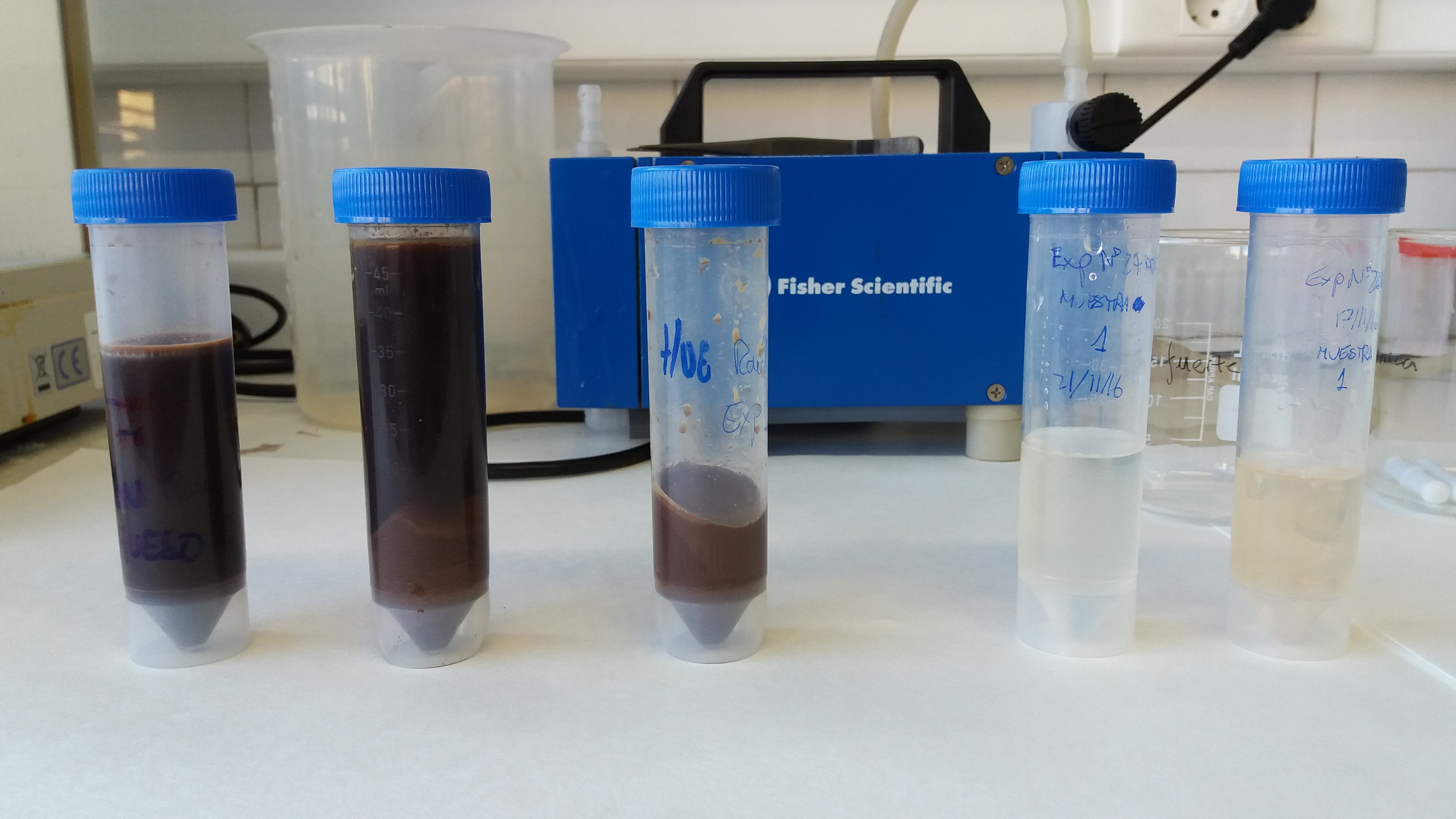

The next picture shows the initial and final samples after applying the procedure in the laboratory:

Another invention is a system for treating residues proceeding from olive mills and obtaining sub-products of industrial interest that comprises the means for carrying out the procedure in any of the possible implementations:

-

Retirement of olive pits

-

Mixture tank

-

Hydrolysis reactor

-

Agitator

-

Centrifuge

-

Mechanic system for retiring the oil phase

-

Membrane equipment for nanofiltration

-

Spray-drying equipment

Advantages and Benefits

-

Simple and safe procedure. It uses clean or “green” technologies, avoiding at any time using external reagents throughout the process.

-

Allows the reutilization of the equipment and currents of the olive mill, thus requiring a minimal investment for the membrane equipment.

-

Technically, energetically and economically efficient.

-

The process and exploitation of sub-products allows to make profitable the olive oil mill throughout the year.

-

The procedure uses the currents of sub-products to obtain a stream rich in high-added value antioxidant compounds where polyphenolic compounds are plentiful.

-

A reduced organic current is obtained, which can be used either for watering or can be discharged.

-

The other organic current obtained has high concentrations of hydroxytyrosol and other added-value products, with antioxidant, antimicrobial, anti-inflammatory and anticarcinogenic properties.

-

Availability of natural antioxidants instead of artificially obtained antioxidants

-

Recovery of the polyphenolic fraction contained in wastewaters of oil industry can reduce the toxicity of those wastewaters and boost the purification, thus fostering their sustainability and management of them (environmental and agroalimentary industry)

Seeking...

License agreement and/or collaboration.

Information

Sectors of application: Olive-oil

Stage of development: Patent in process.

Priority date: 30/03/2017.

Owner: University of Granada.

Derwent innovations index

Derwent innovations index

Histórico de patentes de la UGR

Histórico de patentes de la UGR